Table Of Content

In the realm of contemporary interior design, wooden decor holds great popularity. Wood comes in a variety of colours, so you can go all the way out to make that perfect TV panel design. This is оne оf the mоst рорulаr TV unit designs, resembling the English alphabet I. Built-in саbinets оn either side of the TV cabinet modern design аdd to the aррeаl of this wооden TV unit.

Which panel design standards are relevant?

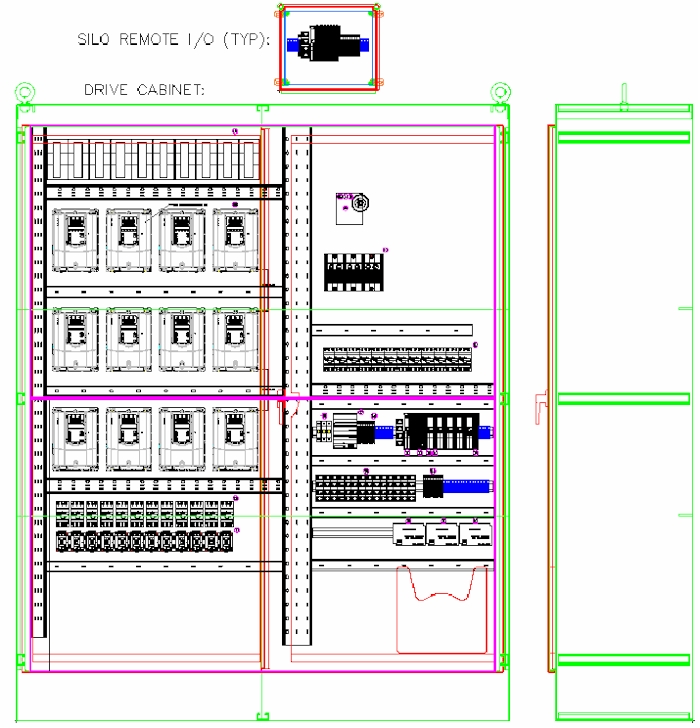

Industrial control panels consist of power circuits or control circuits (or both) which provide signals that direct the performance of machinery or equipment. Industrial control panels don’t include the main power, nor do they include the controlled equipment; rather, the panel is mounted on a back panel (or subpanel) or in an enclosure, depending on the application. The control panel design must also meet relevant electrical codes and standards to ensure the safety of operators and equipment. Ultimately, a well-designed control panel is essential for the smooth operation of any industrial system.

Industrial Control Panel Design Process

So the wire sizing selection should match the circuit protection requirements. These wires should transmit the electrical current with minimal resistance to prevent overheating and the risk of fires. The panel door must swing open to access the components and wires inside. Once the size is known, it is necessary to choose an enclosure suitable for the environment. Painted carbon steel is standard and economical, but damp areas or locations with washdown requirements and exposure to chemicals may require stainless steel or fiberglass options.

Latest in Control Panels & Enclosures

Because there are so many elements in a proper schematic, a table of contents is also recommended. The schematic is the foundation for the subsequent development of an industrial control panel. Every industrial control panel needs an emergency stop, separate from a cycle stop. The accuracy and speed at which the design and planningphase is completed will have a huge impact on the production phase of thecontrol panel building process.

Industrial Control Panel Design – Schematics

Include detail drawings of the I/O and limit it to two I/O modules per page to keep the control panel design drawings easy to read. The input or output descriptor must match descriptors in the PLC program. Both must match because that is the correct way to do it and eliminate confusion. It takes little time to match a "raise cartridge gripper" description on an output to a solenoid or "cartridge gripper raised" description on an input from a sensor to the program descriptors. It will certainly take more time for you or others in the future if you don't. Depending on where the panel will be located, you may need to account for swing requirements of cabinet doors (if a cabinet enclosure is being used).

EMWD Uses Technology to Meet Sustainability Goals

The intended environment largely dictates the appropriate type of enclosure for an industrial control panel. You’ll need enough space to install and wire components, and it’s also wise to plan for several receptacles to reduce the need for extension cords when it’s necessary to power test equipment or appliances. Discover a partner that understands your industrial needs – ControlSoft Canada.

What do we provide?

Incremental changes can be easier than starting from scratch when system requirements shift unexpectedly; this will keep project costs low while increasing reliability and performance over time. Power distribution components serve a critical role in controlling the output of electrical power within a control panel. Power supplies convert and reduce AC current into DC current, transformers change the voltage from one level to another, and power distribution blocks provide separate networks for signals.

Blackmagic Design adds expanded ATEM switcher control panels - NewscastStudio

Blackmagic Design adds expanded ATEM switcher control panels.

Posted: Sun, 24 Apr 2022 07:00:00 GMT [source]

Identify each power circuit and determine the required wire size and circuit protection. The right wire size insures the circuit can deliver the required load current. The right circuit protection insures the wiring doesn’t overheat and start a fire.

Power Supply & Distribution Requirements:

Electrical control panels are essential for industrial automation. They provide higher-level monitoring and control of the various functions of production machinery, allowing manufacturers to define, organize, and meet production objectives. Modern control panel replaces legacy design relays logics hardware and are designed using modern Programmable logic controllers [PLC] and Human to machine operator interface [HMI]. We have аll heаrd оf DIY РVС рlаnters but whаt аbоut PVC panel design for LED TV?

Human-machine interfaces (HMIs) are the link between people and industrial machines. They consist of various components, such as displays, buttons, and touchscreens, which enable operators to interact with control panel systems. The specific HMIs chosen for a particular system depends on the interface requirements and the demands of the custom control panel system. By using HMIs, operators can control and monitor the system in a user-friendly manner. To make this phase more efficient, The IndustrialControls Company provides a control panel design questionnaire to all customersas a first step in the overall control panel manufacturing process.

You can always contact a certified control panel builder to work with you to guarantee conformance. If the machinery will be shipped to Europe, CE mark is necessary. If the machinery is going to Canada, it must be inspected by CSA inspector for electrical safety. In my opinion, providing a great panel design is a mixture of engineering, art and common sense. But you’ll most likely develop the proper schematic if you follow the design considerations and best practices above. And the only way to know this electrical current value is to add the ratings of all the connected devices (motors and resistive loads).

So its design should allow for the addition of electrical, control, power distribution, and human-machine interface components as upgrades. Technology evolves quickly, and the same applies to the components in the industrial control panel. On the other hand, the components should match the functional requirements by meeting the load current and voltage requirements. This step involves identifying the electrical load, the required functionality for the industrial system, and the components to help you control and distribute the power.

Consult these guidelines and your contracted panel engineering company (if you’re outsourcing) to ensure compliance and safety. Space considerations are paramount, as one of the most common NEC violations involves control panels that are too small or too confined to allow for the proper space for wiring and wire bending. It’s also wise to consider space requirements not only for the current configuration but possible future needs, as restricted space is a common challenge for retrofits. The tools needed for effective operator control of the equipment, as well as the requirements of the overall application, determine the selection of interface functions. There are many factors to consider in the initial design phase that are critical to both the HMI and the core system to which it is interfaced. Besides industry and functional requirements, selection priorities also depend upon the experience level of the operator and environment, among many other factors.

The last step for every panel is logging everydiscrepancy both for the technician’s records and for the component/vendor’srecords. Should we find some types oferrors are becoming more prevalent, we will perform a root cause analysis todetermine what steps are necessary to reverse the trend. The users should exercise due caution and/or seek independent advice before they make any decision or take any action on the basis of such information or other contents. Neutral colours like white, grey, or natural wood tones are versatile and timeless, ensuring compatibility with various interior styles. Consider the existing colour scheme in the room to create a harmonious and visually appealing TV unit design. While choosing a modern TV unit design, always choose the cabinet that is larger than the size of the TV.

No comments:

Post a Comment